Pneumatic Cylinder Vs Hydraulic Cylinder: What's the Difference

Posted by OCPneumatics on Jan 16th 2026

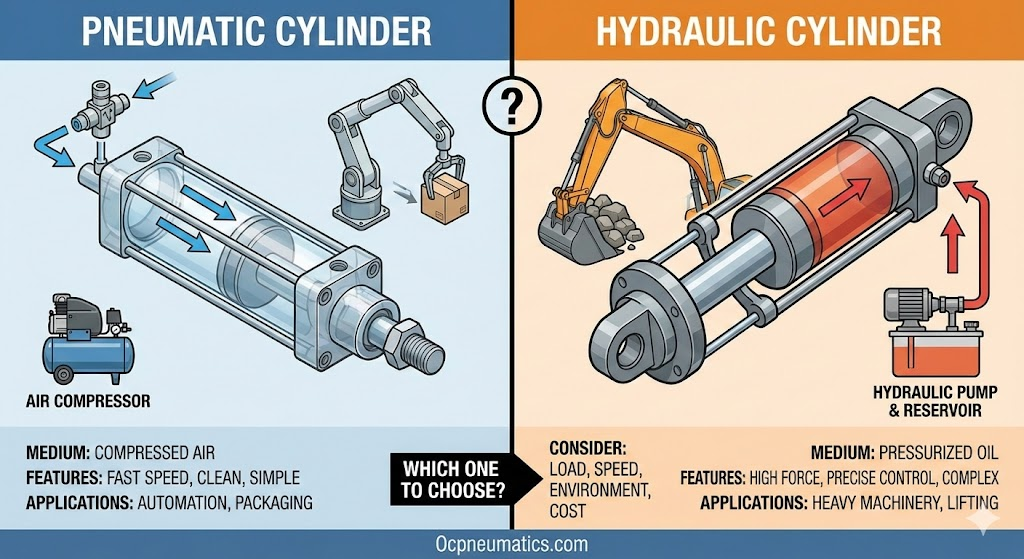

When it comes to making the right choice of motion technology for your industrial equipment, there are times when engineers and purchase managers get confused with questions such as pneumatic cylinder vs hydraulic cylinder. Though both are commonly used to achieve linear motion, they are vastly different from each other. A comparison of both can help you choose what suits your needs better. In this blog, we will introduce you to both and compare them to help you choose what is best suited to your application.

Understanding Pneumatic Cylinder

A pneumatic cylinder functions on compressed air. Air enters this cylinder, thereby moving the piston. These cylinders find applications in various other sectors like automation, packaging, assembly lines, and light manufacturing.

In the case of pneumatic cylinder vs hydraulic cylinder, pneumatic cylinders are known for their simplicity. Pneumatic cylinders are very easy to mount and require less pressure, and are also safer to work in a clean environment. Pneumatic cylinders have less weight and are very responsive and quick.

Another advantage that becomes relevant while comparing Pneumatic Cylinders Vs Hydraulic Cylinders is cleanliness. Here, the medium used is air, and there are no chances of any oil leaks that might contaminate the products or the working area. This makes pneumatic cylinders highly suitable for the food industry and the medical field.

Understanding Hydraulic Cylinders

Hydraulic cylinders function because of the pressurized fluid, usually oil. The oil produces a high amount of force, which pushes the piston in the hydraulic cylinder. The technique has frequently been used in various pieces of machinery.

In pneumatic cylinder vs hydraulic cylinder, one notable feature of hydraulic cylinders is their power. They have the capability of lifting heavy masses with precise force, even when the masses have covered large strokes. This is an important parameter when deciding which cylinder to use.

Moreover, hydraulic cylinders are also heavier and more complicated. They also demand the use of pumps, tanks, and valves. Hydraulics also pose a safety risk where fluids might leak.

Key Design and Performance Variations

In a Comparison Between Pneumatic Cylinder & Hydraulic Cylinder, the following techno-differences become visible:

- Operating Pressure: The Pneumatic cylinders have lower pressure, whereas the pressure used by hydraulic cylinders is very high.

- Force Output: Hydraulic systems produce a much greater force than pneumatic systems.

- Speed and Response: Therefore, Pneumatic cylinders work faster and are more suited for rapid isometric movements.

- System Complexity: Pneumatic systems are simpler compared to hydraulic systems, as there are fewer parts involved.

The pneumatic and hydraulic cylinder difference is one of the most significant factors in determining the appropriate system for your use.

Efficiency and Control

In pneumatic cylinder vs hydraulic cylinder, control is also a major point to be considered. Hydraulic cylinders provide better control over the motions and are smoother, especially while handling heavier loads. Hydraulic cylinders apply constant force throughout the stroke.

Pneumatic cylinders are quite fast but a little less accurate because air is quite compressible. Yet for most uses where precision-matching is not required, this is not a problem. From this pneumatic vs hydraulic cylinder comparison, it can be noted that both are efficient for different uses.

Cost and Maintenance Factors

Cost is one of the major deciding factors in pneumatic cylinder vs hydraulic cylinder comparisons. Pneumatic Cylinders cost less when it comes to setting up an operation. They have fewer parts that need less specialized attention.

Hydraulic systems involve higher capital costs, with frequent checks on fluids, replacement, and prevention of leaks. This can result in increased costs in the long run. However, in heavy-duty setups, the expenses pay off in terms of the power being harnessed.

Safety and Environmental Effect

Safety is also an important consideration in the pneumatic cylinder vs hydraulic cylinder comparison. Pneumatic cylinders are safer compared to hydraulic cylinders because air is non-inflammable. Furthermore, air leakage does not affect the environment.

Hydraulic systems are working at high pressure, and fluid leakages can pose a risk. Appropriate safety and maintenance practices must therefore be followed to avoid accidents. Selecting the proper hydraulic system for the work context and safety standards is thus important.

Typical Applications

Looking at pneumatic cylinder vs hydraulic cylinder in real-world use helps clarify the decision.

Pneumatic Vs Hydraulic Cylinder Uses vary extensively:

- Pneumatic cylinders find applications in packaging machines, conveyors, Pick-and-Place units, light automation, etc.

- Hydraulic Cylinders have applications in forklift trucks, excavators, presses, lifts, and heavy industrial machinery.

These systems are great at what they do in their respective fields. Understanding their applications properly is essential.

Which one should you choose?

Choosing between a pneumatic cylinder and a hydraulic cylinder entirely lies in what you are looking to accomplish. If you require speed, cleanliness, affordability, and ease of use, you need to go for a pneumatic cylinder. But if what you require involves heavy lifting or heavy force, you ought to select a hydraulic cylinder.

There is no one-size-fits-all answer here. Assessing the weight, environmental, cost, and maintenance factors will get you closer to the correct decision.

Conclusion

Knowledge of pneumatic cylinder vs hydraulic cylinder differences assists companies in making the right decisions when acquiring machinery. Both technologies have their advantages and disadvantages, and the best choice to make in this area depends on the way and the context in which the machinery is used.

By carefully considering your project's requirements, you can incorporate the right motion control solutions at Orange Coast Pneumatics.

FAQ

Which cylinder is better for automation?

Pneumatic cylinders are better for automation due to faster response, simple design, low maintenance needs, and clean operation in repetitive industrial tasks.

Are hydraulic cylinders more powerful always?

Yes, hydraulic cylinders generate significantly higher force than pneumatic cylinders, making them ideal for heavy-duty applications requiring strong and consistent lifting power.

Do pneumatic cylinders need frequent maintenance?

No, pneumatic cylinders usually require minimal maintenance since they use air, have fewer components, and face fewer leakage or contamination issues.

Which cylinder is safer to use?

Pneumatic cylinders are generally safer because they operate at lower pressure, use non-flammable air, and reduce risks associated with fluid leakage.

Can both cylinders work together?

Yes, many industrial systems combine pneumatic and hydraulic cylinders to balance speed, precision, and power across different stages of operation.