SMC Pressure Regulator vs Flow Control Valves: What’s the Difference?

Posted by OCPneumatics on Feb 3rd 2026

In pneumatic systems, performance is not only about power. It is also about control, consistency & reliability. Many machines depend on compressed air to function properly, but without proper management of that air, even well-designed systems can become inefficient & unstable.

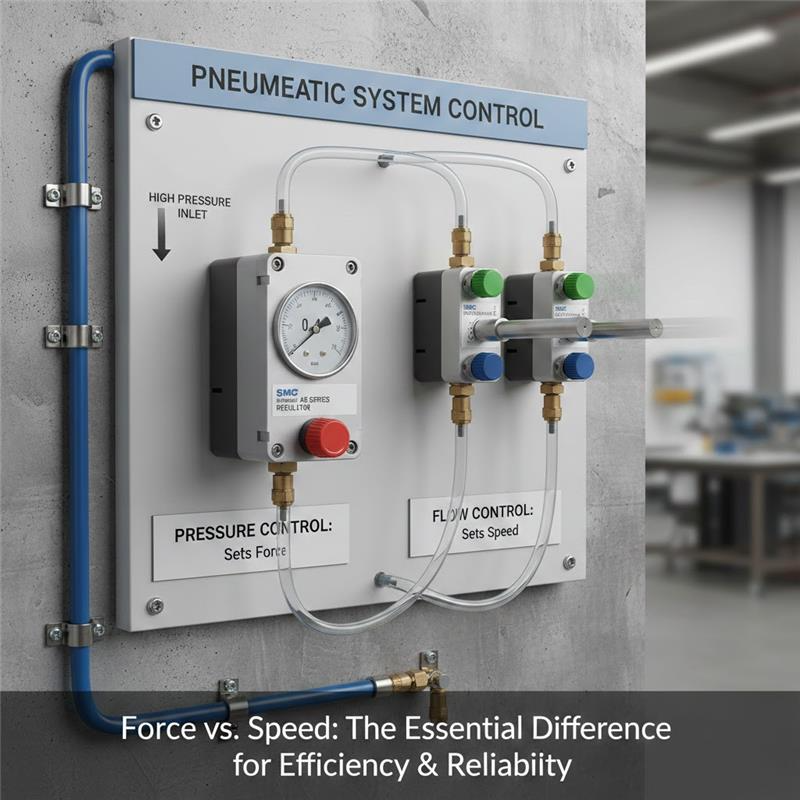

Two components that can confuse buyers & engineers are pressure regulators and flow control valves. Many people assume they perform similar tasks, but in reality, they solve completely different problems. Understanding the difference between them is important if you want smooth operation, better efficiency & longer equipment life.

This guide explains the real difference between an SMC Pressure Regulator and Flow Control Valves, how each one works and why both are essential parts of a proper Air Preparation setup.

The Role of Air Control in Pneumatic Systems

Compressed air coming from a compressor is rarely ready for direct use. It usually needs to be cleaned, stabilized & adjusted before it can safely power machines. This is why air control plays such a critical role in industrial systems.

A good Air Preparation setup helps:

- Keep pressure stable throughout the system.

- Protect sensitive components from damage.

- Improve machine reliability and consistency.

- Reduce energy waste and operating costs.

While both flow control and pressure regulation are components of this process, they deal with very different aspects of the behavior of the air inside the system.

What is the purpose of an SMC pressure regulator?

An SMC Pressure Regulator is designed to reduce high incoming air pressure & maintain it at a stable, practical level. The air from a compressor often fluctuates and these fluctuations can harm equipment or cause inconsistent performance.

This device works by:

- Lowering the high inlet pressure to a safe working level

- Keeping output pressure constant even when demand changes

- Protecting cylinders, valves and tools from overpressure

- Improving consistency in machine operation

When pressure stays stable, machines apply the same force every time. This improves product quality, reduces mechanical stress and makes the entire system more predictable and reliable. In simple terms, this component controls how strong the air force is.

What Are Flow Control Valves and How Do They Work?

Flow control valves focus on something completely different. Instead of controlling pressure, they control how fast air moves through the system. This directly affects the speed at which cylinders and actuators move.

They are mainly used to:

- Adjust the extension and retraction speed of cylinders.

- Prevent sudden or jerky movements.

- Improve smoothness and precision.

- Reduce shock, vibration and mechanical stress

Even if pressure is perfectly set, a machine can still move too fast or too harshly without proper flow control. These valves make sure movements stay smooth, controlled and safe.

Difference Between Pressure Control & Flow Control

The difference becomes very clear when you look at what each one actually controls. An SMC Pressure Regulator controls the level of pressure, which means it controls how much force the system can produce. Flow Control Valves control the flow rate of air, which means they control how fast something moves.

In simple ways:

- Pressure control affects force.

- Flow control affects speed.

- One cannot replace the other.

- Both are required for proper system behavior.

Trying to solve a pressure problem with flow control, or a speed problem with pressure adjustment, usually leads to poor performance and higher wear.

Why Pressure Regulation Is Important in Real Applications

Stable pressure is the foundation of any reliable pneumatic system. When pressure changes constantly, machines start behaving unpredictably. Sometimes they move too weakly and sometimes too aggressively.

Proper pressure regulation helps:

- Keep force output consistent.

- Protect components from damage.

- Improve repeatability of operations.

- Reduce air consumption and energy waste.

Using a perfect SMC Pressure Regulator ensures the system works within safe & efficient limits, which improves both performance & long-term reliability.

Why Flow Control Is Equally Important

Even with perfect pressure, uncontrolled movement can still damage machines and reduce precision. Flow Control Valves allow engineers to fine-tune how fast each movement happens.

They are especially valuable because they:

- Improve motion smoothness

- Increase operator and machine safety

- Reduce mechanical wear and impact forces.

- Allow better control over cycle times.

In applications where timing, positioning and smooth operation matter, proper flow control is just as important as proper pressure control.

Do Pneumatic Systems Usually Need Both?

In most industrial systems, both components are used together as part of a complete air preparation strategy. A typical system does not rely on just one type of control.

Together, they provide:

- Stable and safe working pressure

- Controlled and smooth machine motion

- Better efficiency and longer equipment life

- More predictable and reliable performance

The regulator sets the working force, while flow control valves shape how that force is applied over time.

Where Each One Is Normally Installed

A pressure regulator is usually installed near the air supply or before sensitive parts of the system so that everything downstream receives stable pressure. Flow control valves are normally installed close to the actuators or cylinders where speed adjustment is needed.

This placement ensures:

- Pressure is stabilized before air reaches the system.

- Speed is controlled exactly where motion happens.

- Both controls work together without interfering with each other.

Common Mistakes People Make When Choosing Between Them

Many system problems come from misunderstanding these components. Some people try to control force using flow restriction, while others skip pressure regulation entirely.

Common mistakes include:

- Using flow control to fix pressure issues

- Running systems at higher pressure than necessary

- Ignoring proper air preparation steps

- Assuming one device can replace the other

These mistakes usually lead to wasted energy, faster wear and unstable machine behavior.

How They Work Together in Practical Systems

In real applications, the SMC Pressure Regulator defines how much force the system operates with, while the Flow Control Valves decide how quickly that force is applied. This combination allows machines to be both powerful and precise at the same time.

When both are selected and adjusted correctly, systems become smoother, safer and far more efficient.

Conclusion

Understanding the difference between pressure control & flow control is essential for building efficient & reliable pneumatic systems. Machines perform better, last longer & cost less to maintain when air is prepared properly and the right components are used in the right places.

For high-quality pneumatic components and dependable air management solutions, Orange Coast Pneumatics offers professional-grade products and expertise to support efficient and long-lasting systems.

FAQs

- What is the main difference between pressure regulator & flow control valve?

A pressure regulator controls force, while a flow control valve controls speed.

- Do I need both in one pneumatic system?

Yes, most systems use both for stable pressure and smooth movement.

- Where are these components usually installed?

Regulators go near the air supply, flow control valves go near actuators.

- What is air preparation in pneumatics?

It means cleaning, stabilizing, and properly controlling compressed air.

- Can I control speed by changing pressure only?

Not properly. Speed should be controlled using flow control valves.