What is a Pneumatic Valve? How it works and its Function

Posted by OCPneumatics on Jan 14th 2026

Many machines today depend on air power, and one important part behind this power is the Pneumatic Valve. These valves help control the movement of air so that different equipment can run safely and smoothly. The performance of the entire system often depends on how well the valve manages airflow, whether it is a small automated tool or a large industrial machine. A stable and controlled air supply ensures that machines work with the right speed, force and timing. This is why understanding what a Valve does becomes so important for anyone working with automation, manufacturing or maintenance.

These valves act like the “traffic managers” inside a pneumatic system. They open, close or redirect air so parts like cylinders and actuators can move exactly when they need to. Precise airflow control allows machines to precisely lift, push, hold, press or spin. A system may lose pressure, move irregularly or even stop functioning completely in the absence of proper valve control.

What is a Pneumatic Valve?

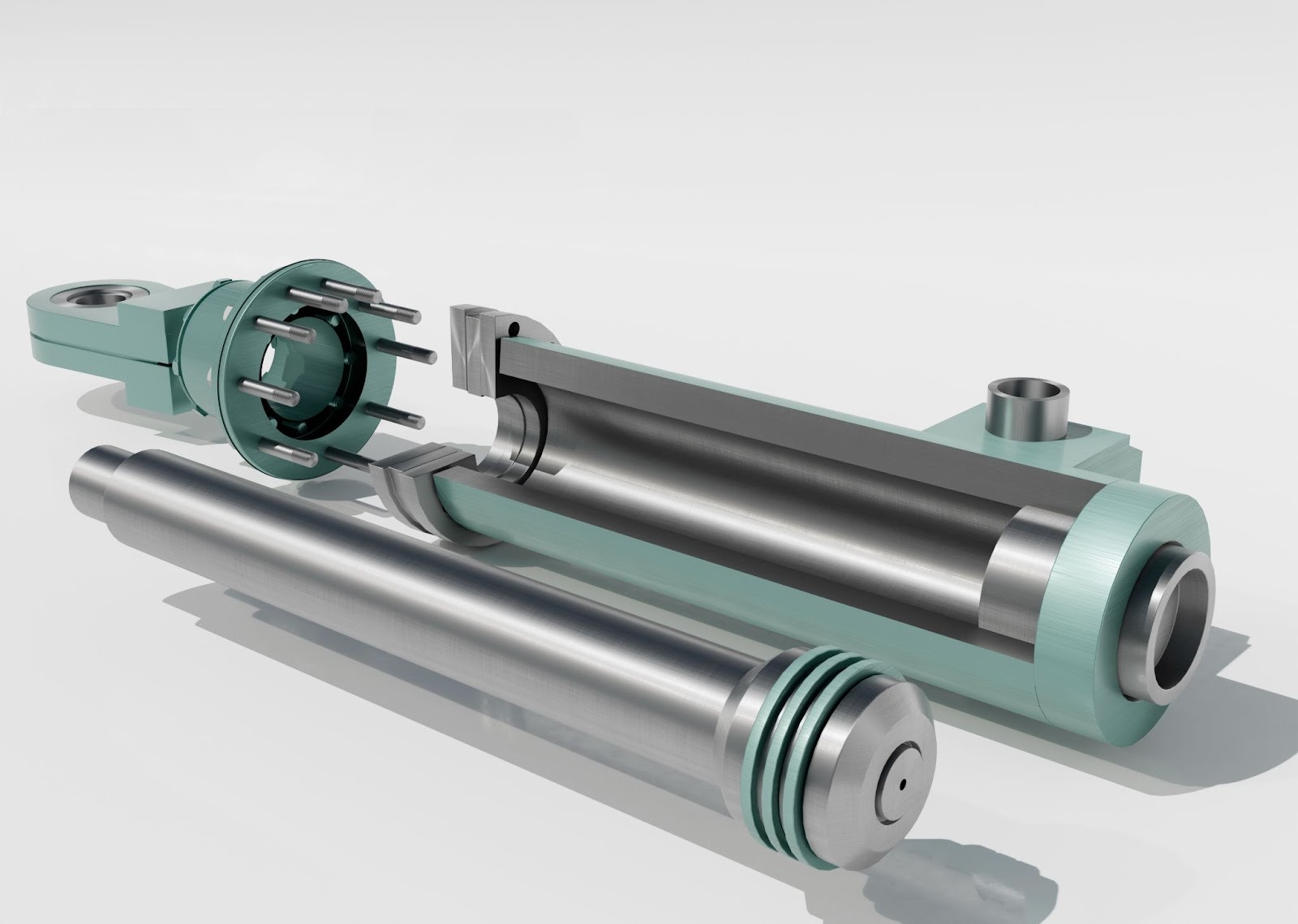

A Pneumatic Valve is a device that controls the flow, direction or pressure of compressed air inside a system. It works like a controller that decides where air should go and how much air should enter a machine. Many valves are designed to respond instantly, which helps machines perform quick and accurate movements. Some are operated manually, while others use air signals or electrical signals to shift automatically.

These valves keep the system steady by making sure each part gets the right amount of air at the right moment. A good valve is important for the proper working of air-powered tools, cylinders and actuators. Without it, machines can lose power, move slowly or stop working. That’s why this part is one of the most important pieces in any air-powered system.

How a Pneumatic Valve Works?

A Valve works by opening, closing or redirecting airflow when a signal is applied. This signal can be manual, electrical, mechanical or air-triggered. Once the valve receives the signal, the internal spool or disc moves to change the flow path.

Here’s How The Basic Working Process Looks:

- Compressed air enters the valve from the main supply.

- The internal mechanism shifts based on the control signal.

- Air is then directed to extend or retract the connected device.

- Excess air is released through an exhaust port.

A well-functioning Pneumatic Valve helps maintain perfect coordination between airflow and movement.

Essential Roles for Smooth Automation

Every pneumatic system depends on the Valve to perform several important tasks. Its main functions include:

-

Control Air Direction

It directs compressed air to the right port so cylinders or actuators move correctly. This guarantees that equipment runs in the intended order, avoiding misalignment or unanticipated movements, which is essential for preserving workflow effectiveness and security.

-

Maintain Pressure Levels

The Pneumatic Valve helps keep the pressure stable, preventing system damage. Balanced pressure increases the life of equipment and lowers the possibility of leaks or unexpected breakdowns. This allows systems to run constantly and avoid unplanned downtime.

-

Manage Airflow

It regulates the speed of air to make movements smooth instead of fast. Proper airflow control reduces mechanical stress on moving parts, ensuring smooth operation, precise positioning and better control over automated processes.

-

Turn Air Supply On or Off

Some valves simply act like buttons to start or stop the air supply. This function is important for safety, allowing operators to shut down systems rapidly for maintenance or emergencies, reducing the risk of accidents.

These functions make the Valve essential for safe and efficient operations.

Types of Pneumatic Valves

A Pneumatic Valve comes in different types based on how it controls the system.

Common Types Include:

- Directional control valves for setting the airflow path

- Pressure control valves for managing air pressure

- Flow control valves for adjusting the movement speed

- Solenoid valves that use electrical signals

In many industrial machines, these valves also work alongside advanced process Valves, which help with automated control systems in larger applications.

Applications Driving Reliable Performance

A Pneumatic Valve is useful in many industries because it delivers clean, fast and reliable performance. You can commonly find them in:

- Packaging machines

- Food and beverage automation

- Automotive manufacturing

- Robotics and material handling

- Medical devices

- Assembly and production lines

Their reliability and easy maintenance make them an ideal choice across different sectors.

Why These Valves Improve Operations

A Pneumatic Valve offers multiple benefits that make pneumatic systems efficient:

- Quick response times

- Long service life

- Safe operation in sensitive environments

- Low maintenance

- Smooth, controlled movement

- Easy installation and replacement

These advantages help companies boost output and reduce failure.

How to Choose the Right Pneumatic Valve

The ideal valve depends on some important factors.

Here’s What You Should Consider:

- The pressure range your system needs

- Number of ports required

- Airflow capacity

- Type of actuator or cylinder

Choosing the correct valve ensures stable performance and long-term durability. Some systems also use check Valves to keep airflow moving in a single direction, which helps prevent unwanted reverse pressure.

Conclusion

Choosing the right components for any air-powered system can make a major difference in performance, safety and long-term reliability. A machine's activities become more effective and reliable when its components function well together. Understanding how each part functions also helps prevent downtime and reduces maintenance needs. It also supports better decision-making when upgrading or repairing equipment.

Reliable products and expert guidance play an important role in keeping systems running without interruptions, and Orange Coast Pneumatics provides dependable solutions that support a wide range of industries. With the right equipment, any operation can maintain steady performance and improved productivity.

FAQ

- How quickly do pneumatic valves respond?

Most pneumatic valves respond almost instantly, allowing precise control of cylinders and actuators for fast industrial operations.

- Can pneumatic valves work in extreme temperatures?

Yes, many valves are designed to operate reliably in both high and low temperature industrial environments.

- How often should pneumatic valves be maintained?

Routine inspection every 6–12 months ensures optimal performance and reduces the risk of unexpected system failures.

- Are pneumatic valves suitable for automation systems?

Absolutely, these valves are essential for automated machinery, robotics, and production lines requiring accurate airflow control.

- What happens if a pneumatic valve fails?

A failing valve can cause airflow loss, slow operations, or complete system stoppage, affecting productivity and safety.